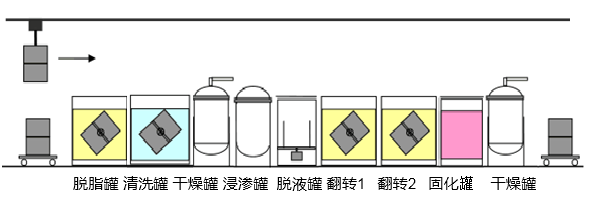

Sketch map of equipment for degreasing, turning and impregnating

Suitable for machining (multi thread hole), oil casting and threaded hole (M3) machining oil castings, customers do not have cleaning equipment, while cleaning products with high surface cleanliness.

Equipment features:

1. 、 ultrasonic degreasing and reverse spraying system are adopted to ensure the cleaning of products

2. vacuum drying, saving drying time, providing high production efficiency and beat

3. to six by centrifugal dewatering system, can make the product six of the threaded hole infiltration agent centrifugal drying, compared to the traditional four centrifugal dewatering system to reduce infiltration agent consumption, save the cost, but also provide favorable conditions for the next step of cleaning

4. using the spray cleaning system, can make the product screw hole six surface clean no residual night, no longer need to use air gun to blow the threaded hole residual liquid artificial, artificial blowing air gun to blow the artificial environmental protection, can not guarantee that all can blow to each hole every time (visual fatigue)

5., equipment investment is slightly larger, saving a lot of labor, very cost-effective

6., PLC and automatic control are adopted to reduce labor cost

Equipment effect diagram